General LED lighting

CRI 80-95

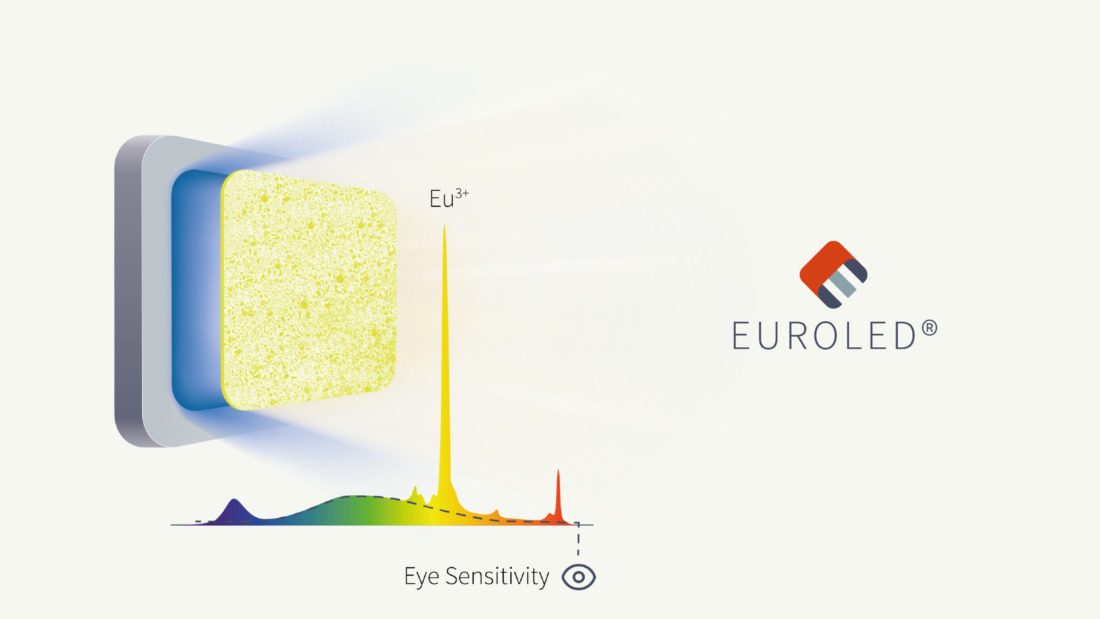

A patented warm white nano-engineered Eu³⁺-based phosphor solution that provides stability, low saturation, color tunability, and 10% to 20% more lumens per watt for CRI 80-95 LED applications.

EuroLED® is a patented LED technology, built on advanced nanomaterials that replace traditional phosphor systems with a more efficient red and green phosphor combination. This nano-engineered Eu³⁺-based solution delivers up to 10–20% more lumens per watt for warm white CRI 80–95 applications, while maintaining color stability, low photo-saturation, and excellent thermal performance. Fully compatible with existing LED manufacturing processes, EuroLED® is easy to adopt and scalable for both indoor and outdoor use. From general lighting to high-CRI environments, it offers a reliable path to higher efficacy without sacrificing quality. Designed for stability in mid- and high-power LEDs, EuroLED® performs consistently, even in the most demanding conditions.

EuroLED® delivers up to 10–20% more lumens per watt, helping you get more light from every electrical watt, without compromising color quality.

Engineered for long-term spectral consistency, EuroLED® maintains accurate color across time, temperature, and production batches.

Its modular nanomaterial design allows precise control over the color output, making it adaptable for a wide range of CRI levels, color temperature, and lighting environments.

Fully compatible with existing LED manufacturing processes and with a production process without hydrofluoric acid, EuroLED® is easy to integrate, scale up, and license for global applications.

Our proprietary nanoparticle technology is built on the inter-particle energy transfer (IFRET) principle.

We combine two purpose-built nanomaterials:

By engineering these two materials at the nanoscale and positioning them with precision, energy absorbed by the sensitizer is transferred directly to the emitter, which then emits the desired color.

While energy transfer between ions is not new, conventional methods embed both ions in a single host material. This often leads to quenching, where the light is lost due to uncontrolled interactions between ions, making the blue absorption of Eu³⁺ particularly problematic.

Our breakthrough lies in decoupling the materials. By choosing separate hosts for both the sensitizer and emitter, and by precisely controlling the distance between them, we enable efficient energy transfer while preventing performance losses.

This design flexibility means we can fine-tune each component for optimal absorption, emission, and stability, without any compromise.

To learn more, explore our scientific publications on this proprietary technology:

Whether you’re a lighting manufacturer, technology partner, or investor, we’re always open to meaningful collaborations. EuroLED® is ready for market. Let’s explore how we can bring this innovation to life together.

Our insights give you the full story, from core science to practical impact.